Successfully Added

The product is added to your quote.

If your facility still relies on Allen-Bradley 1336 PLUS drives, you're running on borrowed time. These legacy units are obsolete, hard to replace, and prone to failure, putting your uptime at serious risk.

In 2025, modernization isn’t optional. Parts are scarce, repairs take longer, and unplanned downtime costs more than ever.

This guide helps maintenance managers, controls engineers, and technicians successfully migrate from the 1336 PLUS platform to the PowerFlex 750.

👉 For full wiring diagrams and step-by-step instructions, download the official 1336 PLUS to PowerFlex 750 conversion manual here.

The Allen-Bradley 1336 PLUS series was reliable, but here’s why you should upgrade to the PowerFlex 750 series:

It’s been discontinued for nearly two decades.

Factory support is limited or unavailable.

Replacement parts are harder to source.

Power components age and degrade.

HIMs and software tools lack forward compatibility.

Minimize unplanned downtime

Improve drive performance, diagnostics, and efficiency

Gain compatibility with modern PLCs and EtherNet/IP

Access advanced safety and control features

Future-proof your system with scalable architecture

Before removing any drive, it's essential to document everything—from parameters to wiring and communication protocols. A failed drive risks losing parameters, forcing your team to guess.

An electrician or technician who can accurately trace and document wire terminations

A programmer or engineer familiar with AC drive configuration and parameter management

A controls expert who understands PLC communication and legacy network protocols (if the drive is networked)

Multiple team members often need to collaborate to document everything before decommissioning a 1336 PLUS.

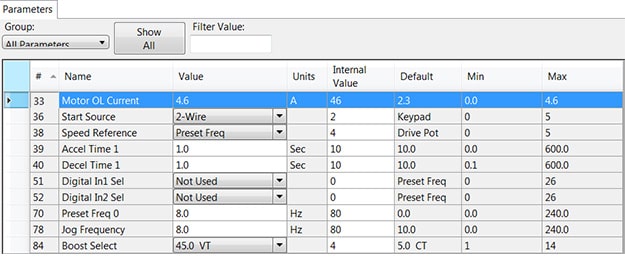

Every 1336 PLUS drive depends on a defined parameter list to control its operation. Losing this information means you'll have to rebuild from scratch, which can cause major delays.

Use the HIM (Human Interface Module) to manually record parameters

Or use Drive Executive (from DriveTools SP suite) to upload the configuration

Optionally use Drive Observer to monitor and trend drive performance before failure

Drive Executive is the go-to tool for parameter management, while Drive Observer enables short-term trending and diagnostics before removal.

If power is lost and the HIM goes dark, you can’t retrieve anything

Your team will need to guess, reverse-engineer, or rebuild logic under pressure

This often results in stressful reprogramming sessions and extended downtime

Modernizing isn’t just about swapping drives—it’s about reconfiguring how they’re wired.

Three-phase power terminals

Digital I/O wiring (start, stop, jog, enable, etc.)

Analog inputs/outputs (speed reference or feedback to PLC)

Legacy network connections (e.g., Remote I/O with PLC-5 or SLC 500)

✅ Label all wires

✅ Photograph terminal blocks

✅ Back up schematics, drawings, and notes

Even small wiring differences between 1336 and PowerFlex drives can cause costly errors if not caught before reinstallation.

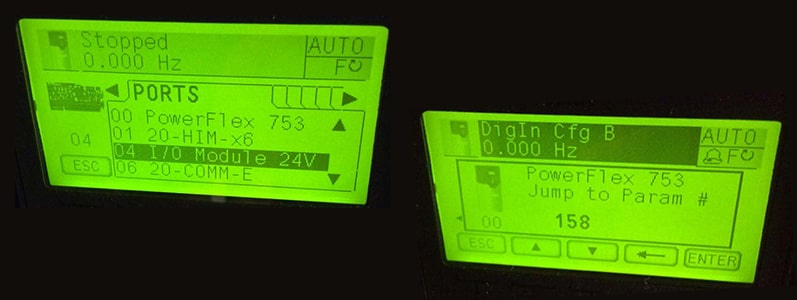

You cannot transfer settings between HIMs due to different communication protocols and speeds—even if the connectors look the same.

| Feature | 1336 PLUS | PowerFlex 750 |

|---|---|---|

| Port | 8-pin Mini-DIN | 8-pin Mini-DIN |

| Protocol | ScanPort | DPI (Drive Peripheral Interface) |

| Baud Rate | 19.2 kbps | 115.2 kbps |

| Software Cable | 1203-USB | 1203-USB |

These differences prevent direct transfer of parameter sets or HIMs between platforms.

To interface with the PowerFlex 750, use:

1203-USB cable

RSLinx, Connected Components Workbench (CCW), or Studio 5000

Don't assume a one-to-one terminal match, even if the drive application is simple. You must remap I/O logic to the new drive’s terminal assignments and parameters.

Understand how the PLC controls the drive

Check whether you use 2-wire or 3-wire control

Adjust analog references and feedback logic

Update control parameters in the PowerFlex 750 to reflect new terminal maps

This guide focuses on the PowerFlex 750 series, with the 755 model highlighted in our real-world example for advanced applications.

Scenario:

A manufacturing plant uses a 10 HP Allen-Bradley 1336 PLUS drive on a critical conveyor system with 3-wire control, a 0–10V speed reference, and a Remote I/O network tied to a PLC-5. Facing downtime risks and obsolescence, they upgraded to a PowerFlex 755.

Migration Approach:

1. Parameter Backup & Planning

2. Drive Selection & Installation

The PowerFlex 755 was chosen for:

3. Wiring Reconfiguration

4. Network Upgrade

5. Commissioning & Testing

Final Outcome:

Mistakes during modernization can result in downtime, damage, or operational issues. Avoid these common pitfalls:

Failing to back up 1336 parameters before removing the drive

Reusing wiring without verifying terminal changes

Skipping input remapping, causing unexpected behavior

Ignoring safety features, especially STO requirements

Assuming plug-and-play network compatibility

Using the wrong HIM or cable

The PowerFlex 750 series is an advanced modern drive platform with robust control, safety features, and flexible I/O options to scale your system needs. Understanding its models and key features will help you select the right unit for your application.

PowerFlex 753: Ideal for standard applications like fans, pumps, and conveyors.

PowerFlex 755: Best for advanced control tasks that require precise torque, positioning, feedback, and customizable I/O.

V/Hz, Sensorless Vector, and Closed-Loop Vector control

Built-in Safe Torque Off (STO) for enhanced safety

Modular I/O and option card support for flexible customization

Premier Integration with Logix controllers, making setup seamless

Configure using HIM, Studio 5000, or Connected Components Workbench (CCW)

Logical parameter groupings simplify setup

Pre-built drive AOPs streamline integration with Logix controllers

📘 Step-by-Step Conversion Manual: Download Now