Successfully Added

The product is added to your quote.

Industrial Automation Co, located in Raleigh, NC, is a global reseller of hard-to-find and obsolete industrial automation parts. We offer comprehensive customer support and a top-tier warranty on all products

Even as Industry 4.0 drives a wave of connected factories and smart analytics, many production lines still rely on proven legacy hardware. These systems—robust, familiar, and field-serviceable—remain the backbone of global manufacturing. From classic PLCs to rugged drives, the following ten components continue to be essential MRO staples in 2025....

Even as Industry 4.0 drives a wave of connected factories and smart analytics, many production lines still rely on proven legacy hardware. These systems—robust, familiar, and field-serviceable—remain the backbone of...

Supply chains aren’t predictable anymore — they’re volatile ecosystems where component shortages, extended lead times, and freight delays have become routine. For manufacturers, that means one reality: if you don’t...

In industrial automation, downtime costs thousands per hour — and replacing entire control systems can cost millions. That’s why many facilities turn to refurbished automation parts as a smart, budget-conscious...

When a variable frequency drive (VFD) or servo amplifier reaches end-of-life, finding a direct replacement isn’t as simple as matching horsepower. It’s a precise engineering decision that impacts control performance,...

Downtime is one of the most expensive words in manufacturing. Every minute a production line sits idle because of a failed or missing part means lost revenue, missed deadlines, and...

Maintenance is no longer just about fixing what breaks—it’s about predicting what will. In 2025, forward-thinking manufacturers are using data-driven insights to move from reactive maintenance to predictive strategies that...

Explore all posts from Industrial Automation Co, a global reseller of obsolete industrial automation parts

Human Machine Interfaces

Human Machine Interfaces

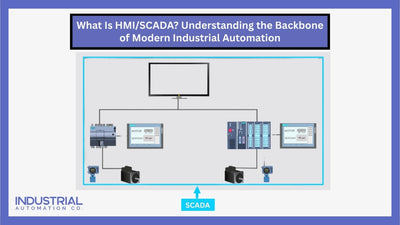

HMI/SCADA systems are the unsung heroes of industrial automation. From managing large-scale utilities to fine-tuning factory operations, these platforms are central to how we monitor, control, and optimize complex processes....

Drives & Motors

Drives & Motors

AC drives aren’t just for adjusting motor speed. In today’s industrial world, they’re enabling energy recovery, precision control, and automation in ways that might surprise you. From elevators to solar...

Drives & Motors

Drives & Motors

In the world of industrial automation, performance upgrades don’t always mean a full system overhaul. For OEMs and engineers managing aging equipment, the Mitsubishi FR-A740-00120-NA strikes the ideal balance: modern...

Comparison Guides

Comparison Guides

When it comes to reliable servo drive performance, Mitsubishi’s MR-J2S series remains one of the most trusted options in industrial automation. But within that series, choosing between the Mitsubishi MR-J2S-100B and...

Maintenance

Maintenance

When your Mitsubishi MR-J2S servo drive starts acting up, the first instinct may be to replace it. But not so fast—many MR-J2S issues are solvable with proper troubleshooting, and in many...

Drives & Motors

Drives & Motors

Counterfeit servo motors are becoming a growing threat in today’s global supply chain—and the Mitsubishi HG-KR23BK is no exception. Whether you're buying a replacement unit or maintaining a critical system,...

Drives & Motors

Drives & Motors

Introduction: Old Name, New Demand In the fast-paced world of industrial automation, most servo drives fade from relevance within a few upgrade cycles. But Mitsubishi’s MR-J2S-100B continues to buck that...

Drives & Motors

Drives & Motors

When every second of downtime costs thousands, upgrading your servo system isn’t just a technical decision—it’s a strategic one. The Mitsubishi HG-KR23BK is quickly becoming a top choice for engineers looking...

Drives & Motors

Drives & Motors

In the world of CNC automation, precision and repeatability aren't just features—they're requirements. As we move through 2025, Mitsubishi Electric remains a top name in servo and control technology, delivering...

Technology Insights

Technology Insights

Artificial Intelligence (AI) is no longer a futuristic buzzword—it's a practical tool reshaping factories, processes, and production floors in real time. In 2025, the integration of AI into industrial automation...

Drives & Motors

Drives & Motors

When it comes to CNC automation, the right servo drive can make the difference between a seamless retrofit and weeks of troubleshooting. In 2025, two Mitsubishi models are standing out...

Human Machine Interfaces

Human Machine Interfaces

Mitsubishi Electric’s GOT2000 series represents a major leap forward in operator interface technology. These high-performance human-machine interfaces (HMIs) combine advanced graphics, intuitive controls, and reliable industrial design—making them ideal for...