Successfully Added

The product is added to your quote.

Servo drives are everywhere in technology and manufacturing, thanks to their high level of precision. The use of these devices is only expected to grow, with the worldwide market exceeding $19 billion in 2026. But what is a servo drive? How does it work?

To answer those questions and more, we'll explore the primary servo drive basics. We'll also look at the systems that use these devices and some different servo drive applications.

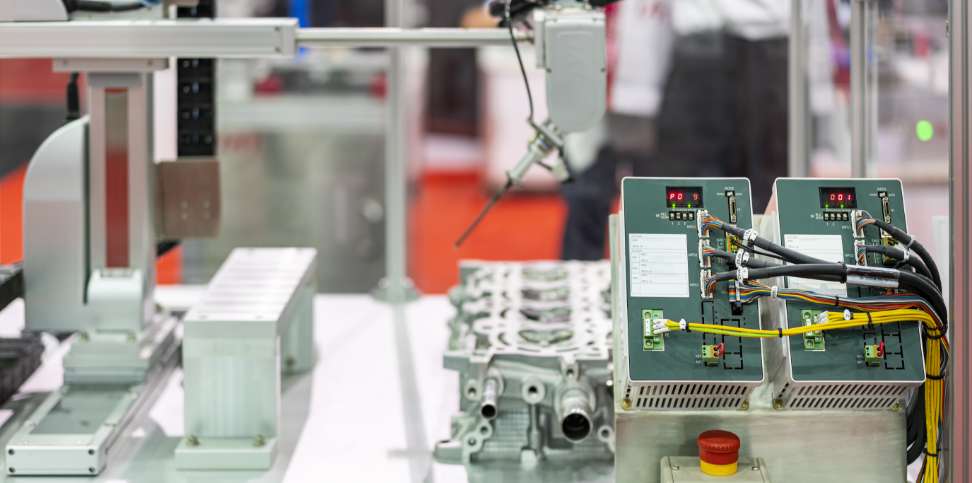

A servo drive is a small computer that automatically controls a motor's velocity, torque, and position. It's made up of microchips, circuit boards, wires, and connectors.

A servo drive modulates the power supply voltage and current to control a motor and functions as part of a more extensive system.

A servo drive system is an automated closed-loop system designed to facilitate the precise movements of a motor. Besides a drive, a system includes:

Also known as an amplifier, the drive takes the command from the controller and amplifies it into high-voltage messages to manage the motor's torque, power, and speed.

The encoder is behind the precision of these systems. Open-loop systems without encoders continue working regardless of the outcome. Think of it as a heater that continues to heat water indefinitely until the user turns it off manually.

In a closed-loop system, an encoder monitors the output and feedback so the system can adjust its actions accordingly. This would be like a heater that heats water to a predetermined temperature, then automatically shuts down once it reaches said temperature.

The drive works with the encoder, taking the provided information, processing it, and sending messages back to the encoder to fine-tune the motor's speed and position.

In some instances, drives may be combined with servo controllers to reduce the space taken up by the system.

Now that we know the basics, let's look at servo drive applications. The technology may be simple, but it's used in highly specialized technology and machines you may encounter daily. Some of the most common applications include:

Cutting raw materials and metal into precise shapes is essential in the manufacturing. Without this precision, parts of machines will not fit together correctly, leading to faulty machinery at best and dysfunctional at worst. A servo system is critical for any equipment used to create these parts, including:

Servo systems are also highly involved in computer numerical control (CNC) machining, one of the most crucial processes in manufacturing today.

In the material handling industry, more and more warehouses are turning to automation to help improve workflow and efficiency. Some automation systems include a goods-to-people (GTP) picking system in which autonomous robots help move products from shelves to workers.

Since most customers prefer to avoid crushing their products, precision is paramount regarding how these machines pick up and carry items. Servo systems provide the necessary accuracy to get the job done.

It's easy to associate satellites with highly specialized scientific functions or lousy television reception. But satellites are a vital part of our everyday tasks, such as:

These things cannot function without autonomous antenna positioning systems that accurately angle satellite dishes skyward. Drives help position the satellite dishes and make precise shifts according to feedback from the system.

We often take for granted how easy it is to get a camera to focus when taking a picture. These days, cameras come equipped with autofocus, which adjusts the distance between the lenses of a camera until you have a perfectly focused image.

For a function like this to work correctly, you need a system that can make the slightest movements and adjust them on the fly, depending on the feedback from the image. Drives meet that need and are in most cameras with autofocus.

Print technology has come a long way from the printing press. Digital print technology enables incredible speed and accuracy for even the most complicated jobs. 3D printing allows us to print everything from phone holders to prosthetic limbs.

Both processes (but 3D printing especially) require continual feedback between the computer and printer to render the image or object accurately. This is another opportunity for drives to shine, and they can often be found on the extruders of 3D printers.

An explosion is a mighty force. Because of this, it can grow out of control very quickly with deadly consequences. Even so, a surprisingly wide variety of industries utilize explosives regularly, including:

Controlling explosions is a delicate science that often requires robots with refined bomb detonation technology. Many of these robots use drives to ensure the most precise movements possible.

Despite the significant number of people who fear elevators, there hasn't been a reported elevator free fall since 1945, and for good reason. Elevators contain a plethora of safety features, including cables that can each hold the weight of a car and specially designed safety brakes.

Servo motors also act as an additional safety feature for elevators by helping ensure accurate movements throughout the ride. And servo systems help monitor the speed of the elevator as it travels.

Industrial Automation Co. is the go-to source for quality CNC servo drives that work in numerous systems. Our drives deliver superior performance, increased precision, and outstanding energy efficiency. We offer unparalleled service and turnaround times to ensure our customers have the industrial automation parts they need when they need them. Start shopping today for the components that will keep your operations up and running.