Successfully Added

The product is added to your quote.

Servo drives are integral to industrial automation, where every process must be performed quickly, accurately, and efficiently. The role of servo drives in achieving unparalleled accuracy and control will only continue to grow as industries push the boundaries of technology and innovation. But how does a servo drive work?

This article will explore how a servo drive works and detail the servo drive working principle.

Before we answer the question, "How does a servo drive work?" let's discuss exactly what a servo drive is. In simple terms, a servo drive is an electronic device made of microchips, circuit boards, wires, and connectors. It tells an electric motor how to operate in a very detailed way, controlling the motor's speed, torque, and position. It's like having a very smart remote control for a motor, allowing it to move just the right amount at just the right speed. Servo drives take in electricity and convert it into precise movements, making sure that machines can do things like cut materials to an exact size, move goods to a specific spot, or rotate items to the perfect angle.

Standard drives, like those you might find in fans or drills, simply start and stop their motors, maybe changing speed in a rough way. But servo drives are different — they're all about control. They monitor the motor's every move, adjusting it in real-time to be as accurate as possible.

If a standard drive is like using a light switch to turn a lamp on and off, a servo drive is like having a dimmer switch plus a color and angle adjuster — it gives you complete control over the light's intensity, color, and direction. This level of control makes servo drives invaluable in modern machinery, where precision is essential.

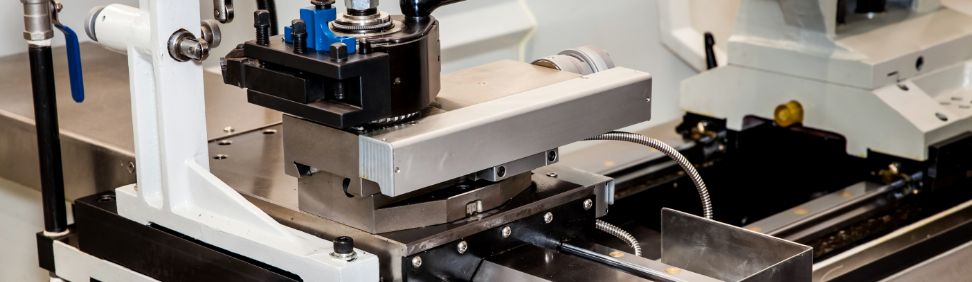

Servo drives are versatile and can regulate motors of varying sizes. For instance, they might control smaller motors found in the elbow joint of a robotic arm. On the other end of the spectrum, they also handle larger motors used in heavy industrial equipment or in the wheels of electric vehicles. Essentially, the more powerful the motor, the more robust the servo drive needs to be.

Now, let's look at how a servo drive works. To control a motor, a servo drive manages and guides electric current through the motor's wiring. Without a servo drive, a motor could spin wildly without direction or fail to move entirely.

It all starts with the controller, which ranges from something as basic as a knob to as sophisticated as a computer program.

This controller dispatches a signal — a precise, minor burst of electricity — to the servo drive's command input. The servo drive, in turn, boosts this signal to generate the necessary current or voltage for the motor.

The servo drive gets the energy to boost the signal from the drive's power source, which could be a battery or a main electricity connection. This source supplies a steady flow of voltage. The servo drive then allocates this power to the motor, modifying it as required in response to the controller's commands.

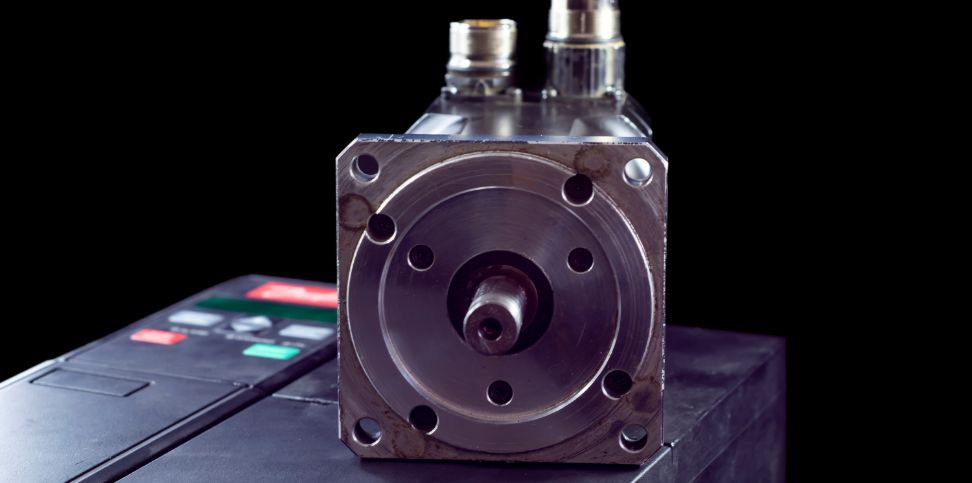

An electric motor consists of two principal components: the rotor, which rotates and is connected to the shaft, and the stator, which remains stationary and is fixed to the frame. One of these elements contains permanent magnets, while the other houses wire coils, also known as electromagnets, which are activated when the servo drive sends current through them.

Activating different sets of these coils in sequence creates a rotating magnetic field. This interacts with the fixed magnets, causing the rotor to turn.

The amount of current flowing through the coils controls the torque, while the voltage governs the motor's speed. By meticulously adjusting the current and voltage, the servo drive precisely manages the motor's torque, speed, and position.

Feedback is part of everyday life. Your car's speedometer lets you know if you need to adjust your speed. A kitchen thermometer tells you if your roast is cooked to perfection. Similarly, a feedback mechanism or encoder lets a servo drive know if it needs to adjust the current or voltage.

This feedback loop is critical as it enables the servo drive to adjust the electricity flowing to the motor in real-time. The encoder's role in the feedback loop is vital. It acts as the eyes of the system, providing constant, real-time updates on the motor's status. This feedback enables the servo drive to make instantaneous adjustments, ensuring the motor's performance aligns precisely with the set commands. This adjustment lets the motor operate with the correct torque, speed, and position despite any external disturbances.

Take the incremental encoder, a typical feedback mechanism that monitors rotational movement. Imagine an external force unexpectedly slows down the motor. The feedback device records the motor's actual speed and sends this information back to the servo drive. The servo drive then compares the actual speed against the desired speed and adjusts the motor's power accordingly, ensuring it returns to the correct speed.

The fundamental working principle of a servo drive is based on the closed-loop control system. This system is pivotal in achieving the high levels of precision and efficiency for which servo drives are known. In a closed-loop system, the servo drive operates in a cycle of continuous feedback and adjustment to maintain the motor's operation within the desired parameters. The controller, power source, and feedback mechanism all work together to create the continuous feedback cycle that allows the servo drive to control the motor.

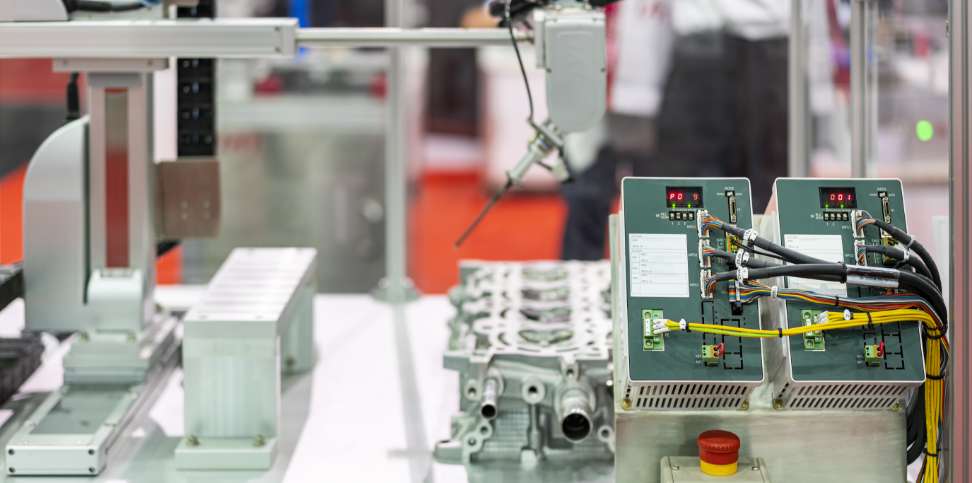

Industrial Automation Co. offers a comprehensive lineup of servo drives, including CNC servo drives. You can find the top servo drives from leading manufacturers in our collection. Browse our selection today for the precision drives your application demands.

Servo drives offer a broad array of advantages crucial to industrial automation. Understanding these benefits is essential for appreciating why servo drives have become indispensable across industries:

As a player in the $6 billion servo drive market, Industrial Automation Co. is ideally situated to answer your questions about how a servo drive works. Read the following for more information.

Servo drives quickly control a motor's speed, torque, and position. In contrast, VFDs are paired with induction motors in applications requiring velocity control.

Leading manufacturers frequently report 20,000 to 30,000 hours lifespans for their servo drives.

Yes, servo drives can be repaired.

Now that we've answered the question, "How does a servo drive work?" you're ready for the next step. Industrial Automation Co. has an outstanding collection of servo motors. We also offer unparalleled customer service and excellent turnarounds, with many in-stock drives ready for same-day shipping. Shop now and experience the Industrial Automation Co. difference.